History

The HOFMANN

Tradition since 1919: How it all began and how it continues.

1919

At the beginning of the first German democracy in 1919, the brothers Hubert and Leonhard Hofmann founded a company in Windsheim’s Spitalgasse, on the ground floor of the former vocational school, to manufacture agricultural machinery.

1925-1927

In December 1925, Leonhard Hofmann passed his master craftsman examination, and in November 1927 the company relocated to the Schellenfeld, today’s Hofmannstraße. With the construction of a new iron foundry and an assembly hall, the company presented itself in a strong and promising condition.

1936

During the economic upswing, HOFMANN built another production hall in 1936 for the manufacture of ball bearing housings and band saws.

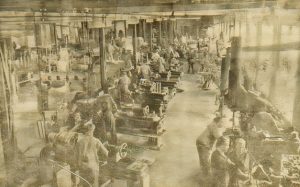

1939

By 1939, the factory employed 122 people. The transition to a wartime economy — HOFMANN became an armaments supplier — initially proceeded without major disruptions. However, shortages of manpower due to employees being drafted into military service, as well as increasing scarcity of raw materials, made production progressively more difficult.

1945-1946

In 1945, production materials and steel were extremely scarce and could only be obtained using government-issued ration certificates. Using leftover materials and remaining stock, the company began by producing kitchen stoves. As early as 1946, however, a new foundry could be built. As production expanded, the company manufactured parts for irons, bench vises, and saw-filing machines.

1948

After the currency reform of 1948, HOFMANN participated in the 1st Handwerksmesse (Crafts Fair) in Munich.

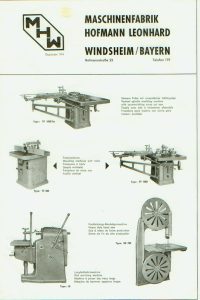

Production of drilling and woodworking machines began. The manufacture of drilling machines was discontinued after several years. HOFMANN ultimately focused exclusively on woodworking machinery and completely shifted production in this direction.

1950-1951

The company’s presence at the Hannover Fair in 1950 marked the beginning of new customer acquisition. A key factor in sustained revenue growth was the start of export operations in 1951.

1955

Continual expansion of the business led to the construction of a larger foundry in 1955. In addition to covering internal needs, this facility also produced castings for customers and for electric motors.

1982-1987

In 1982, machines were delivered to the USA for the first time. At the 1985 Handwerksmesse in Munich, the company’s innovative thickness planer was awarded the State Prize with a gold medal. In 1987, the machine was further improved with a continuously variable, frequency-controlled feed speed.

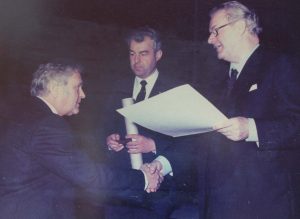

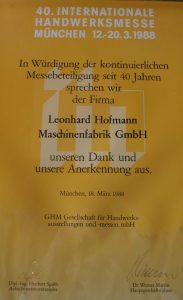

1988-1990

In 1988, HOFMANN received an award for 40 years of participation at the 40th Handwerksmesse in Munich.

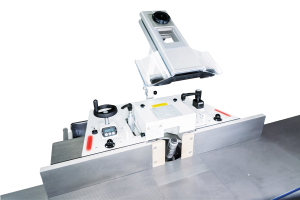

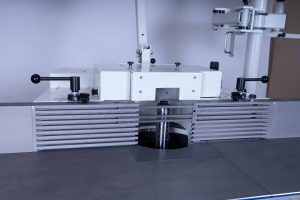

One year later, the unique AD combined jointer-thicknesser replaced the previous Combi machine. For the first time, thickness planing was possible without folding up the jointer table.

The reunification of the two German states in 1989/90 stimulated economic growth and accelerated the company’s modernization.

1994-1995

On July 8, 1994, HOFMANN celebrated its 75th anniversary together with employees and business partners. On July 1, 1995, Ernst Hartmann’s daughter, Gabriele Hartmann, joined the company. She successfully expanded the market across nearly all of Europe. Today, the export share already amounts to 65%.

Continuous modernization continued in the summer of 1995 with the construction of a new assembly hall.

1996-1999

In 1996, HOFMANN launched its first electronically controlled spindle moulder. The TFS 2000 model featured nine spindle speeds that could be selected without changing the V-belt — a technical sensation at the time.

In 1999, the company received the “Special Supplier” award from TEMACO eG.

2000

The turn of the millennium brought the founding of the sales company HOFMANN Maschinenfabrik GmbH in 2000. The combination of state-of-the-art production technology and long-standing experience became the hallmark of HOFMANN Maschinenfabrik. The dedicated and highly motivated employees embody this promise.

2002

A prime example of this corporate philosophy came in 2002, when – after long and extensive development — the Universal Spindle Moulder UFM 210 VISION was unveiled. This machine was a true world first: the spindle tilts up to +95.5°, and all axes are moved via the spindle itself. A patent was filed for the machine.

2004-2006

In 2004, the new milling machine generation with the TF / TFS 1245 models replaced the previous TF / TFS 1200 series.

In 2005, HOFMANN became one of the first manufacturers to introduce an HSK interface for quick cutterhead changes. In 2006, the company celebrated a major milestone: over 100 UFM 210 VISION machines had been delivered.

2007

In 2007, HOFMANN introduced the new “entry-level” TFS 107 spindle moulder to great acclaim. At the LIGNA trade show in Hannover, the UFM 210 VISION was presented with its modern touchscreen control system.

2008-2009

In summer 2008, another production hall was built. By late August, the turning shop moved into it. In October of the same year, one of the most modern DMG brand lathes went into operation. The same year also saw the presentation of the “Multi-Step” moulder — the only moulder capable of automatic multi-step profiling.

In 2009, HOFMANN celebrated its 90th anniversary.

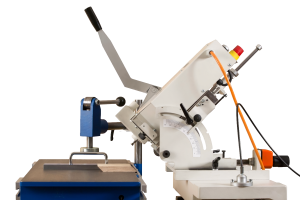

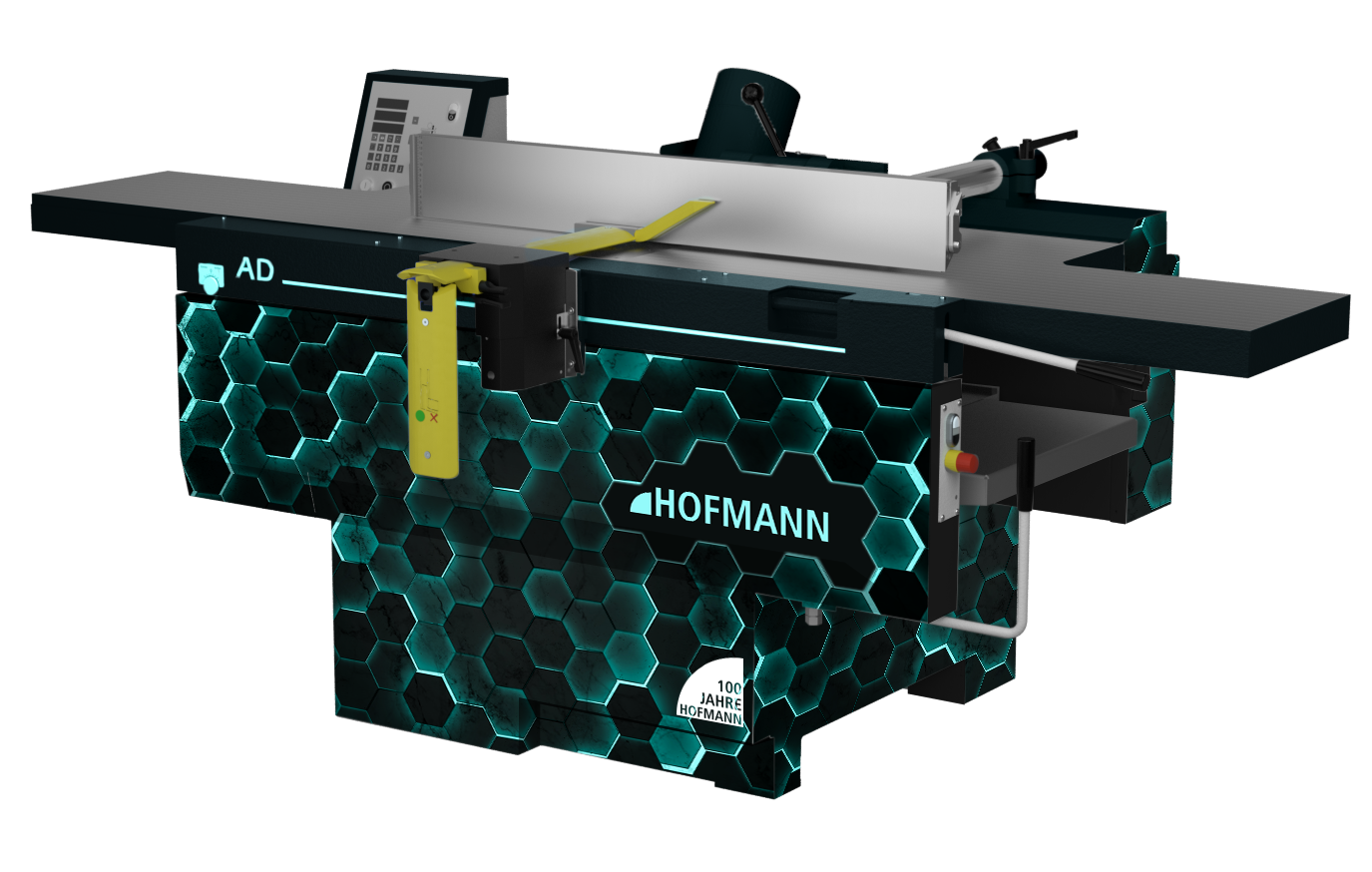

At the 2009 LIGNA anniversary show, HOFMANN presented a limited special edition of the combined AD 514 / 634. This machine embodied the company’s philosophy more consistently than any other.

2010-2013

In 2010, the TF 106 straight spindle moulder was presented at Holzhandwerk as an economical solution. The new generation of fence systems — Type 2601 Basic and Effizient — also debuted, including a special version with an additional spindle.

In 2011, a new design was introduced at HOFMANN. The combined AD 515/635 and the TF/TFS 1245 were the first machines to feature the updated look. Another innovation: the spindle moulder was now available with a 5.7″ touchscreen.

In 2012, the next machine generation followed with the newly designed AHW 412/512/632 jointers, featuring electric adjustment with LED display for hollow/straight jointing. Under the motto “pure efficiency,” the TFS 1260 was presented at the LIGNA for the first time.

In 2013, the new D 636 thickness planer replaced the previous D 632 model.

2014

At Holzhandwerk in Nuremberg, many new developments from HOFMANN were unveiled. Among them was the LB 760-ELA long-hole and dowel milling machine, developed in cooperation with Lachner. Also introduced: the new “AIR-Lock” spindle fence with Guardian.

2015-2016

In 2015, the new LB 770 “OmniFact” long-hole and dowel boring machine was presented for the first time. The name derives from the Latin “omni facere.”

With the CNC software update in 2016, the QR Manager was developed and presented at HHW. Tool and program data could be created on a PC and imported into the machine control system via USB.

2017

In 2017, HOFMANN introduced numerous innovations in the areas of safety and ergonomics. LED light strips were added to the spindle fence for operator safety. The “Guardian” safety system was further enhanced. Additional quick-clamping mechanisms for the fence jaws provided even greater convenience and speed during adjustments.

2018

HOFMANN introduced the latest generation of 2620 spindle fences and the improved comfort function stand. The company also exhibited for the first time at the IWF in Atlanta. During the same period, administrative areas were modernized.

2019

HOFMANN celebrated its 100th anniversary. At LIGNA 2019, the company presented its flagship combined machine in a modern anniversary “Future Design.”

To mark the occasion, a state-of-the-art 5-axis machining center was acquired.

2020

Despite the challenges of the global pandemic, HOFMANN remained committed to quality and innovation. The company continued to rely on proven technologies and upgraded existing machines with practical improvements to enhance safety and ease of use. The new touchscreen control was introduced for CNC-controlled spindle moulders.

The HOLZ-HANDWERK trade show in Nuremberg, scheduled for spring 2020, was cancelled due to the pandemic.

2021

HOFMANN continued investing in modern manufacturing. At the end of the year, a 5-axis machining center of the type BX-500 DD from PINNACLE was commissioned.

The focus remained on further developing proven machine technology with particular attention to ergonomic design, user-friendly operation, and sustainable production.

2022

On June 2, 2022, Senior Director Ernst Hartmann passed away at the age of 93 — a defining figure and long-time shaper of the company.

The new LB 780 long-hole and dowel boring machine replaced its predecessor, the LB 770. Precise linear guides and larger adjustment ranges distinguish the new model.

2023

The oldest production hall underwent extensive renovation. Sustainability and energy efficiency were key priorities: new roof insulation and investment in a photovoltaic system helped reduce energy consumption.

2024

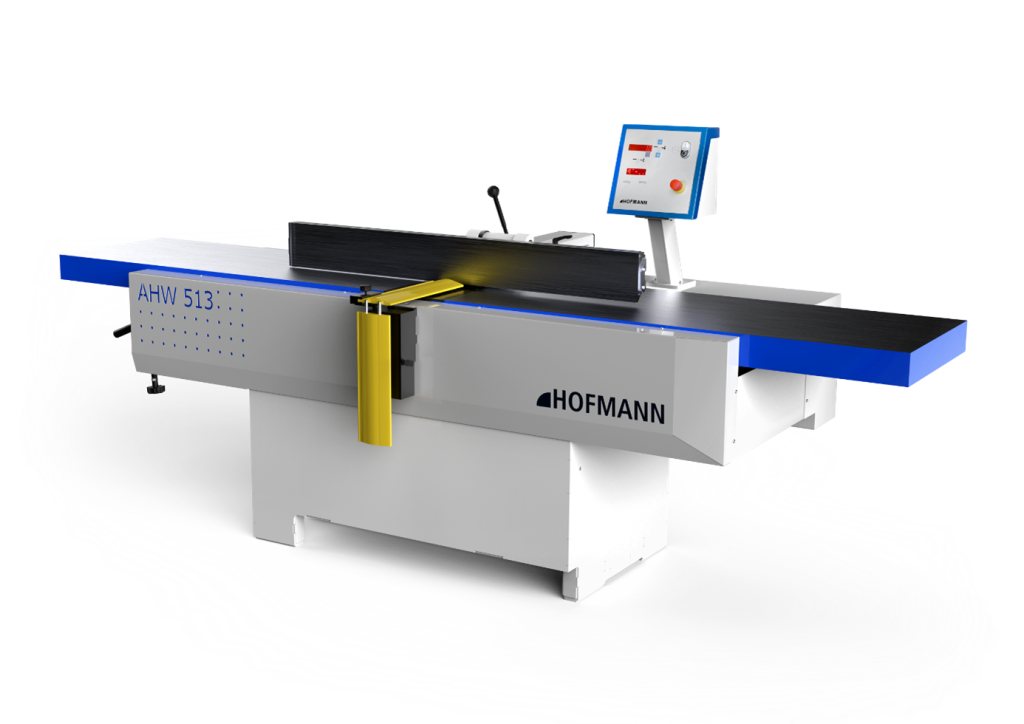

HOFMANN invested in modern, ergonomic workstations in production to further improve working conditions.

At HHW in Nuremberg, the new AHW 513 jointer was presented for the first time.

2025

A major investment was made to modernize the paint shop. The facility was upgraded to state-of-the-art technology to further enhance efficiency, quality, and environmental performance.