Milling fence type 2620 (instead of standard fence type 2601 Efficient)

- Total adjustment via handwheel according to LCD display

- Possibility to switch to tool zero dimension

- Digital display for individual jaw adjustment

- Doubly guided fence with larger clamping surface for the fence jaws and

- Double clamping

- Including quick clamping system for the stop jaws

- Stop adjustment to the center of the milling spindle

- After lifting the stop, the entire table is freely available

- No reference run needs to be carried out after reconstruction

AIR-LOCK for milling fence type 2620

Both fence jaws are pneumatically released and clamped. The clamping of the jaws is monitored – if they are not clamped, the machine cannot be started.

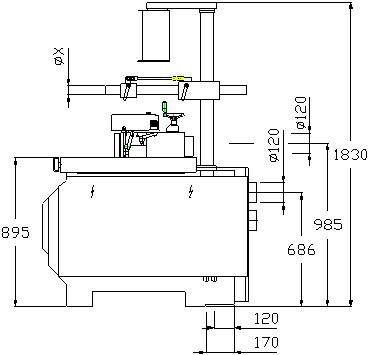

Swiveling device for milling fence, attached to the control panel column via a joint

the entire fence is raised or lowered via a hand crank

Splinter guard aluminum anodized, per piece

Anodized safety rulers (5 pieces) and fillet board for the casting jaws

Integral fence jaws 500/650 mm or 650/650 mm, instead of cast iron fence jaws

Filler rod and spacer, for the integral stop jaws

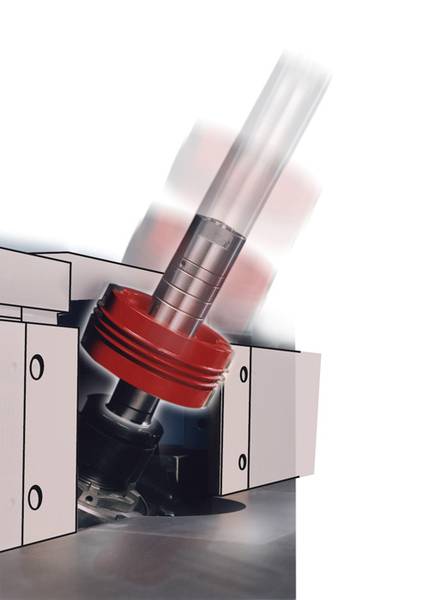

Milling arbor Duo Ø 30 mm HSK-F63, clamping length 140 mm

Milling arbor Duo Ø 40 mm HSK-F63, clamping length 160 mm

Collet chuck for HSK-F63 – without collet

Collet for HSK-F63, available from Ø 6 – 25 mm in 1 mm increments

Feeder type 2048

Motor 0.75 kW, 4 rollers, 8 speeds, incl. stand with counter, horizontal tube 1050 mm, comfort adjustment lever

Feeder type 408 with function stand

Motor 0.75 kW, 4 rollers, 8 speeds, adjustment lever Komfort

Stepless speed control for feeder, 400 Volt / 50 Hz / 3 phases) Operating elements in the control panel

Feeder equipped with air nozzles

For blowing off/cleaning the milling table. Air blast is activated by pressing a button. Air volume can be adjusted using a regulator

Console for feeder stand; if this is not to be mounted on the table

Consoles not available with function stand

Sliding carriage incl. eccentric clamp

- For mounting on the machine table · Height above table 58 mm

- Usable table size 410 x 225 mm, total length 1,050 mm

- Max. workpiece clamping length 1.20 – 1.50 m · Travel distance approx. 710 mm

- With hardened guide shafts and adjustable, high-precision rollers

Protective hood for sliding carriage (for tool-Ø from 250 to 350 mm)

Arc milling master (Aigner)

Kickback protection for insert milling with 2 infinitely adjustable fastening shafts

Counter fence with dial gauges, for exact milling to format, adjustment range 90 mm, standard passage 165 mm

Template holder, attached to the control panel

HOFMANN Guardian (Patent)

- Clamping of the milling stop jaws is monitored (if they are not clamped, the machine cannot be started)

- This prevents unintentional retraction of the stop jaws by the feed

- 2 LED signal lights (for right or left jaw) in the control panel

Safety light bar on the milling fence, warning lights on the fence light up when the spindle is running (only for fence type 2620)