Combined Jointer-Thickness

Planer

AD 515 / 635

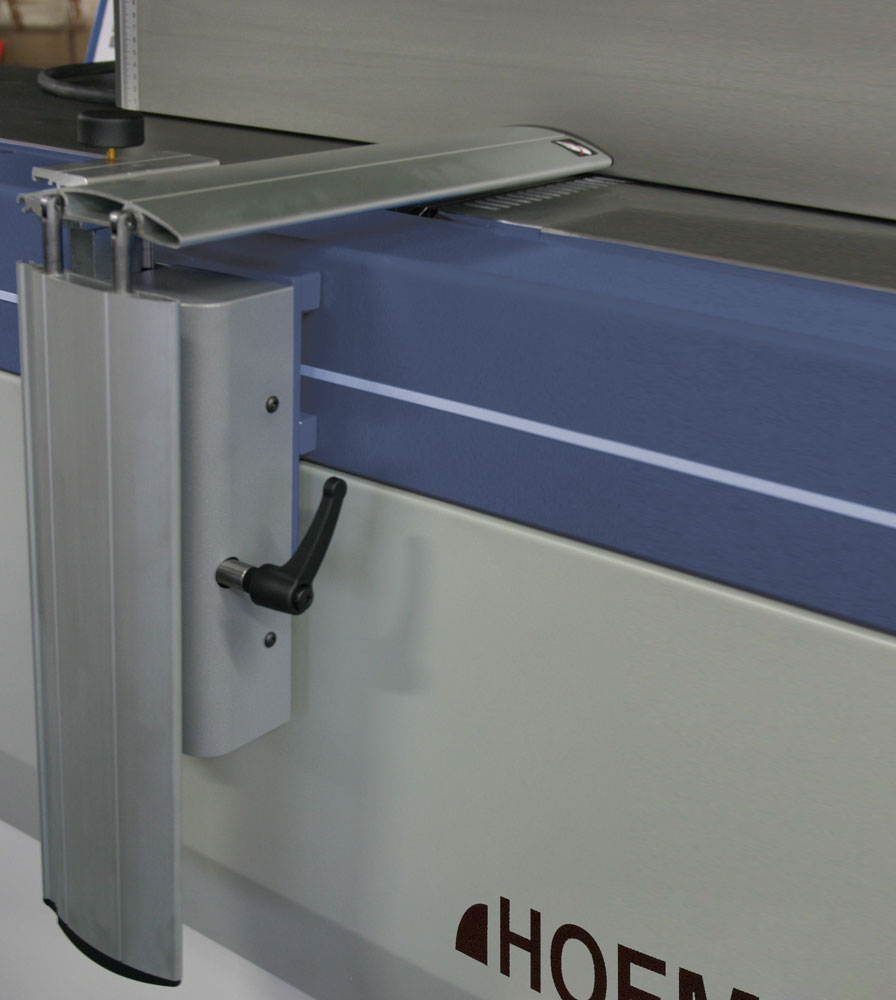

Strong on its own – unbeatable together.

This unique combination of a jointer and thickness planer allows both operations without table change – even simultaneously. This can result in time savings of up to 25%.

The jointer tables can be folded up or down in any position of the thickness table, which is another outstanding feature. The renowned HOFMANN build quality and well-thought-out ergonomics complete the package.

Discover more about the Combined AD 515 / AD 635. In the 360° view, rotate left or right and use the + icons to access additional details.