UFM 210 Vision

The revolution of the table milling machine – the unthinkable becomes possible!

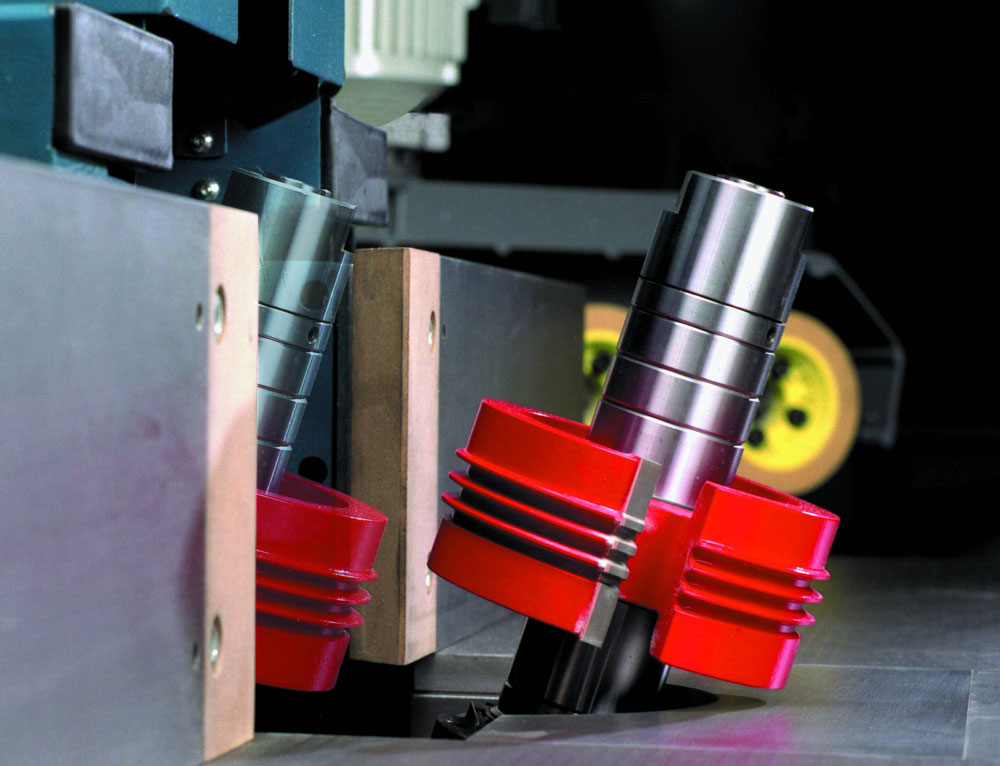

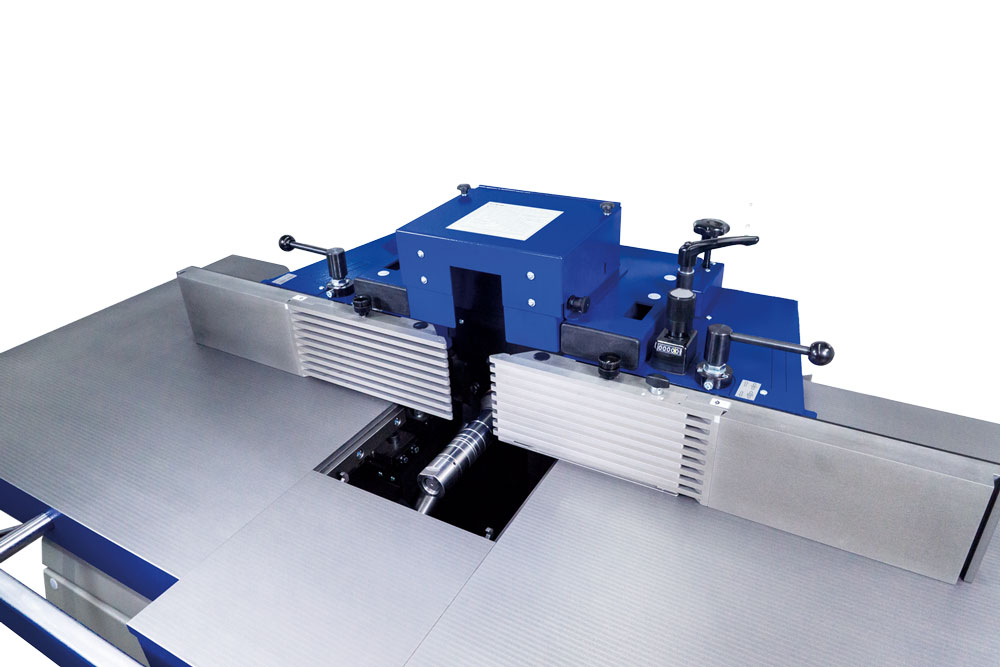

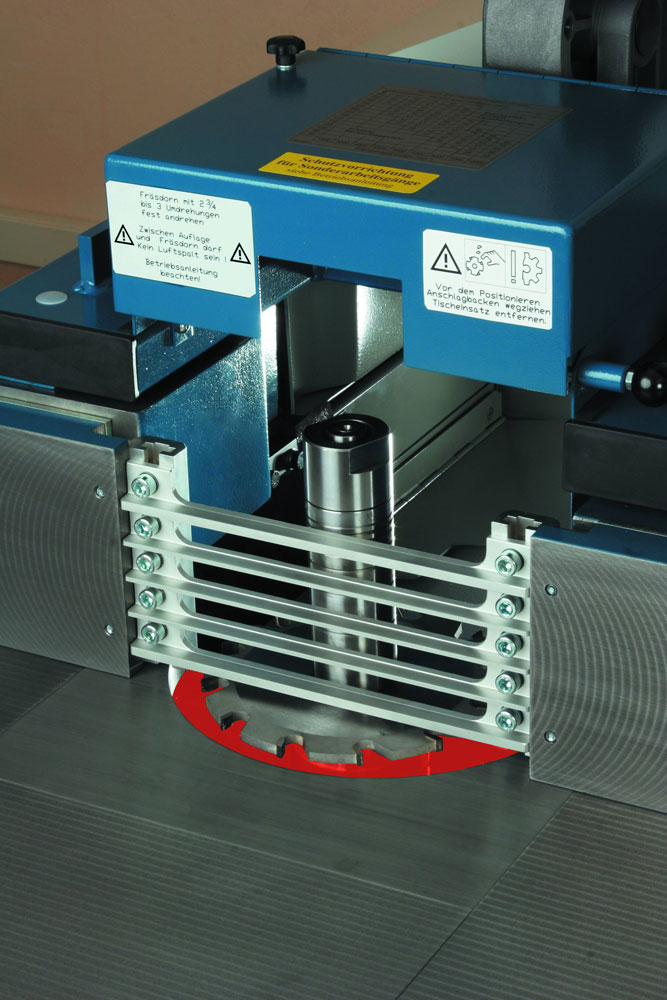

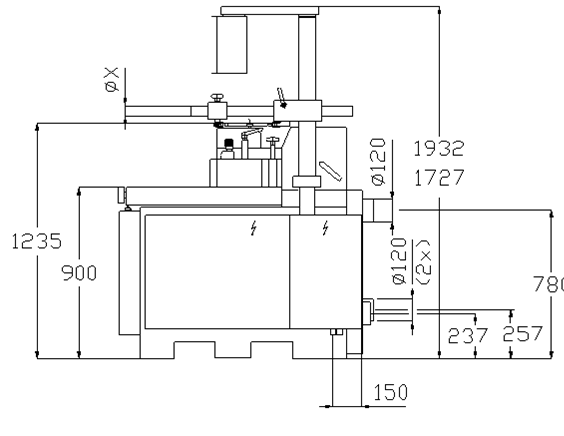

Thanks to the swivel range of the spindle from – 45.5° to + 95.5°, completely new application areas are made possible – there are no limits to your imagination. Another highlight is that the depth is also adjusted via the spindle, so the stop remains fixed. The linear height adjustment rounds off the uniqueness of this machine. Our extremely user-friendly touch control also makes this milling machine unbeatable in terms of efficiency and speed!

Learn more about the UFM 210 Vision universal milling machine. Swivel left and right in the 360° view to get more information via the + symbols.